By Vani Bahl, Published December 8, 2014

CHENNAI: The image of a ‘factory’, as propagated by the Industrial Revolution, is that of a smokestack polluting the sky, hot and dangerous exposed assembly lines, and dark and dingy manufacturing houses. Hero — the world’s largest manufacturer of two wheeled automotives — is all set to revolutionise the factory model at their newest manufacturing plant in the arid north-eastern part of Rajasthan in Neemrana. With the help of globally acclaimed sustainable architect, author and thought leader William McDonough + Partners, Hero MotoCorp is pioneering ‘The Garden Factory’, the new 21st century manufacturing model in India, demonstrating how an industrial workplace can be beneficial, healthy, and even life-affirming. It is an all-in-one green manufacturing plant, producing auto-parts, food and energy.

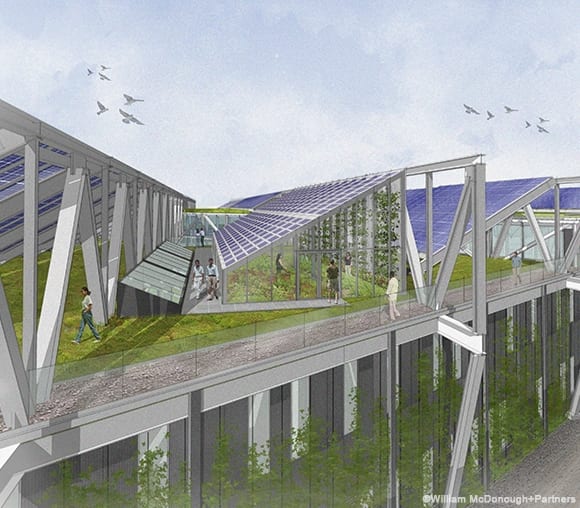

An ‘exoskeleton’, a unique structural feature, has been embedded in the roof which allows trusses to be outside the building, lending interior spatial flexibility to accommodate future equipment changes, and at the same time reducing the interior volume to be cooled. The long span trusses tilt at 45 degrees providing optimum south exposure for the solar panel array, which is used to generate 5.5 megawatts of electricity, powering the air conditioning units in the building. Two Bigfoot air handling units pressurise the building and use the laws of thermodynamics to distribute warm and cool air without the need for ductwork while maintaining a dust free and clean air environment. The waste heat recovery system facilitates and saves energy and costs of water heating and supply.

With biowalls, a vegetated roof and greenhouses, architects have penetrated every possible architectural fabric and space with vegetation to create serene, energy effective and healthy working environments while producing food which supplies the factory canteen and the surplus goes to the community. Rows of greenhouses that have been installed on the rooftop along with the interior biowalls, also aiding in eliminating contaminants, are irrigated with the condensate from the air-conditioning units. The vegetated roof surface, between rows of greenhouses, not only aids in rainwater harvesting but also cools the building and reduces air conditioning load by 20 per cent. The arid landscape around the building has been planted with native and drought resistant trees and shrubs, which will need minimum water only for first six months. This will also help in recharging the aquifer at 1.8x the amount extracted for use in the factory.

The building is designed to provide ample opportunity for observing the rhythms of the sun and weather via continuous skylights and eye-level windows that also decrease electricity costs by providing natural sunlight during work hours. LED lighting and digital controls contribute to an advanced state-of-the art energy effective facility. Break rooms for factory workers provide access to daylight and purified air biowall which uses vegetation to filter contaminants and supplement oxygen.

The building materials and construction systems employed in this project are green, used for their impact on environment and human health. The metal cladding on the front facade meets the criteria of the Cradle to Cradle Certified Products Programme.

Built area of the Garden Factory, comprising the Factory and the Global Parts Centre, will demonstrate eight-fold manufacturing or harvesting-solar power, water for landscaping, oxygen and clean filtered air in interior spaces, hot water, cooling, carbon dioxide for vegetation, food and jobs.

The Garden Factory is a distinct demonstration of a marriage between nature and technology, showcasing possibilities for sustainability in the world of manufacturing — another much needed step towards a green future.

RELATED:

Hero Neemrana Garden Factory project description and photos

Hero MotoCorp “garden factory” in Neemrana | Motown India | October 20, 2014